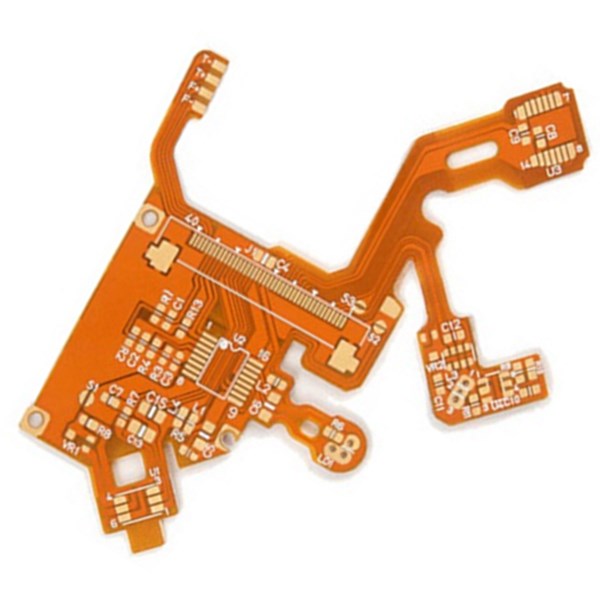

Flex PCB

-

Heartisvery professional flex PCB supplier, youknow,when fabricating flex PCBs, it is important to consider exactly how flexible the PCB needs to be. If it is either too rigid or too flexible, the PCB can break when it is manipulated.

Flex PCBs require very little to no wiring, which reduces wire connection failure, and increases product reliability. While they are quite easy to install in low-tech applications, they become more difficult to assemble as their complexity increases.

Flex PCBs also have a higher material cost than rigid or rigid-flex PCBs. Additionally, they are easily damaged if handled improperly, sensitive to scratching and are difficult to repair.

The manufacture and assembly of flex PCBs fairly similar to traditional PCBs. However, fabricating flex PCBs does require special clamping to hold the material in place during manufacture. High-volume production of complex flex PCBs may require the use of continuous web processing, or “reel to reel” processing.

Our skilled PCB designers have the knowledge to configure flexible PCBs for a variety of project needs. To speak to them about your project, contact Via Technology today!